How Digital Twins Are Changing Asset Management in 2026

- Geoffrey M Green

- Jan 6

- 5 min read

In 2026, the global digital twin market is projected to reach nearly $48.2 billion, as asset owners transition from static "as-built" models to living, data-driven replicas. For facility managers and construction leads, the "Digital Twin" has moved beyond a tech buzzword to become the definitive standard for reducing construction time by up to 25% and slashing operational downtime.

Key Takeaways

Lifecycle Tracking: Digital twins mirror the entire asset lifecycle from design and construction to operations and eventual decommissioning.

Cost Reduction: Shifting to condition-based maintenance via 3D models can reduce overall maintenance costs by up to 20% to 30%.

Integrations: Modern twins integrate with IoT sensors and BIM platforms to provide real-time performance alerts.

Safety: Autonomous robotic data collection removes personnel from high-risk areas while maintaining a 360-degree visual record.

The Shift to Digital Twins

The traditional method of managing assets using scattered spreadsheets and outdated 2D blueprints is no longer viable for high-value portfolios. A digital twin acts as a centralized data nexus, bridging the gap between the physical building and its digital record. Unlike static 3D models of the past, 2026 digital twins are dynamic entities that continuously evolve by integrating high-frequency data from IoT sensors and autonomous robots.

This shift is driven by three core technological pillars:

Real-Time Data Streams: Sensors embedded in critical infrastructure now provide a constant heartbeat of information monitoring everything from pontoons in floating bridges to the blade pitch of offshore wind turbines - allowing for instant anomaly detection.

AI-Native Intelligence: By 2026, twins have moved beyond simple visualization to intelligent, adaptive systems that learn operational behaviors over time and provide context-aware recommendations for performance optimization.

Industrial Metaverse Environments: Platforms like Siemens’ Digital Twin Composer now enable teams to combine 2D and 3D data into photorealistic, physics-accurate visual scenes, facilitating virtual decision-making at unprecedented speed and scale.

By 2026, over 80% of top-tier industrial firms are expected to utilize LiDAR-derived digital twins for continuous site analysis and resource estimation.

At VSI Aerial, we've observed that the most successful managers aren't just "collecting data" - they are using high-fidelity 3D Digital Twins to simulate "what-if" scenarios, allowing them to test structural changes virtually before a single hammer is swung on-site.

Cost Savings of 3D Asset Management

The financial impact of a 3D digital twin is felt most acutely in the reduction of "hidden" operational costs. Inefficiency in file management alone - searching for the right asset or blueprint - is just one example. But beyond administrative efficiency, the move to a digital-first strategy allows for a dramatic shift from high-cost reactive repairs to high-precision predictive maintenance.

Preventive Maintenance: By identifying anomalies early, firms can reduce emergency repair costs. Organizations using these twins report improvement in planning accuracy when compared to traditional scheduled approaches.

Energy Optimization: Real-time monitoring of HVAC and electrical systems via the twin

can lead to up to 20% reduction in energy consumption. This is achieved by revealing poorly insulated zones or equipment generating excessive heat that would otherwise increase cooling and heating loads.

Portfolio Right-Sizing: Facility managers now use operational and cost data within the twin to evaluate the true value of their real estate footprint. This includes analyzing the total cost of ownership - incorporating maintenance, energy use, and downtime - to determine the optimal timing for asset replacement or disposal.

Reduced Capital Expenditure (Capex): Digital twins uncover "hidden capacity" in existing systems, often validating investments in a virtual environment to achieve a reduction in Capex.

We've found that for most enterprise clients, the ROI on a digital twin is realized within 18 to 36 months. Teams are not wasting billable hours on redundant site visits and start making multi-million dollar decisions based on real-world data.

BIM and Enterprise Workflows

In 2026, the line between AEC (Design/Construction) and Proptech (Operations) has blurred. A BIM-integrated digital twin takes static Building Information Models and infuses them with live data streams from IoT sensors and reality capture. This integration creates a "single source of truth" that follows the asset from the first design phase to long-term facility management.

Standardized Data Handover: Instead of a static PDF handover, owners in 2026 receive a digital asset that includes full warranty logs, maintenance history, and live performance metrics.

Real-Time Progress Validation: By comparing live drone scans against the original BIM plan, contractors can detect deviations in real-time, preventing small errors from becoming expensive structural reworks.

Operational Interoperability: Modern twins are built on open standards, allowing them to plug directly into existing Enterprise Resource Planning (ERP) and Computerized Maintenance Management Systems (CMMS).

Decentralized Decision Making: With 5G and edge computing, these workflows allow remote teams to collaborate within a shared 3D environment, reducing the need for high-cost on-site inspections.

Workflow Stage | Role of the Digital Twin | 2026 Efficiency Gain |

|---|---|---|

Design/Planning | Virtual simulation of MEP and structural systems. | Construction time reduction |

Construction | Real-time progress monitoring via drone LiDAR. | Labor cost optimization |

Operations | Centralized repository for warranties and maintenance logs. | Maintenance cost reduction |

Predictive Maintenance & Actionable 3D Models

The ultimate goal of a digital twin is to move from reactive to predictive management. In 2026, advanced machine learning algorithms can predict equipment failures weeks or months in advance.. By simulating actual equipment behavior across multiple data streams, these models identify subtle performance changes that traditional sensors often miss.

Anomaly Detection: AI-driven systems establish a "stable state" baseline for your machinery. By using Recurrent Neural Networks (RNNs) to process sequential time-series data, the digital twin can flag performance deviations such as micro-cracks or bearing wear as soon as they emerge.

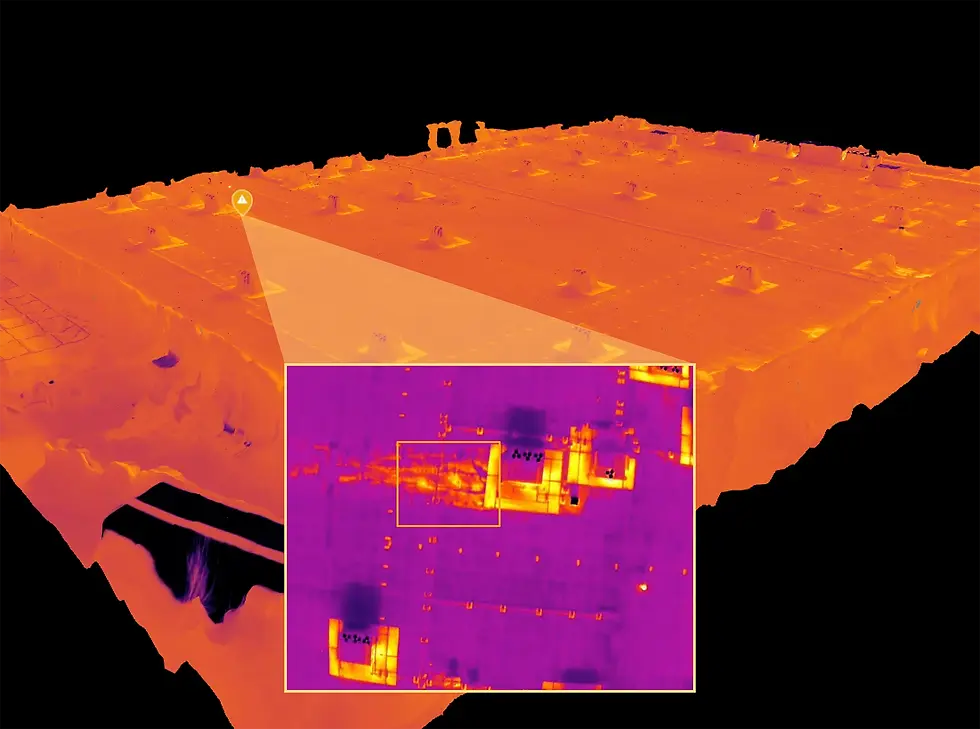

Thermal Intelligence: High-resolution infrared thermography integrated into the 3D model allows for the systematic identification of heat loss patterns and electrical deficiencies. This "Thermal Twin" detects overheating substation components or insulation failures before they escalate into catastrophic system failures.

Physics-Based Simulations: Beyond data patterns, digital twins use engineering-grade simulations to test "what-if" scenarios, such as the impact of extreme weather or increased loads on structural integrity, without risking actual physical assets.

Automated Response Loops: When a potential failure is detected, the system triggers instant maintenance alerts and generates actionable reports, significantly reducing the triage time for maintenance teams.

Our clients are finding that "data readiness" is the biggest differentiator. By standardizing your 3D asset data today, you are building the foundation for AI-driven maintenance that will keep your facility running without surprises for the next decade.

How to Begin Your Digital Twin Journey

Transitioning to a digital twin framework is a transformation, not just a purchase. To avoid the common pitfalls of "data overload," organizations in 2026 are following a structured, phased approach to adoption. Start with a clearly defined, high-value use case - such as a single critical facility or a complex construction project - and scale gradually based on proven ROI.

Define Your Objectives: Identify whether your primary goal is reducing unplanned downtime, optimizing energy, or improving construction site safety.

Audit Your Data Infrastructure: Ensure your current enterprise resource planning (ERP) systems are capable of ingesting high-frequency 3D data streams.

Select the Right Reality Capture: Choose between high-density LiDAR for structural precision or photogrammetry for detailed visual inspections based on your asset's specific needs.

Establish a "Living" Update Schedule: A digital twin is only as valuable as its last update; schedule recurring drone missions to ensure the virtual model stays synchronized with physical reality.

Comments